JHY PCB Blog Hub

Your Source for Expert PCB Design, Manufacturing, and Assembly Insights – Stay Informed with 2025 Trends!

What is a Damper Actuator and How Does It Work?

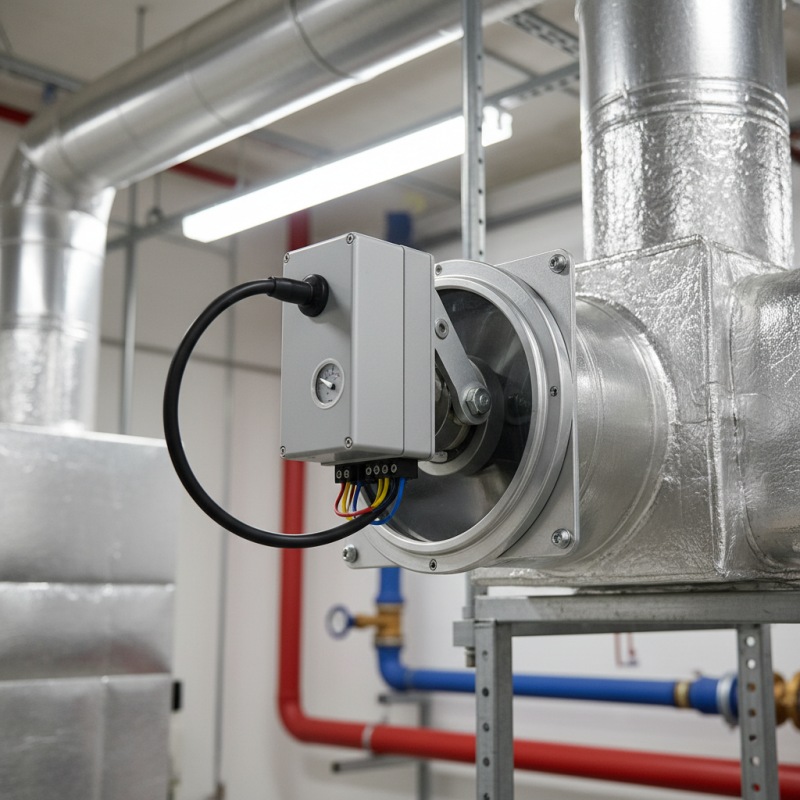

A Damper Actuator is a crucial component in HVAC systems. It controls the airflow through ducts by adjusting dampers. These dampers can open or close based on varying conditions. The way a Damper Actuator operates can significantly affect energy efficiency and comfort levels in a building.

Understanding how this device works is essential. It mostly uses an electric or pneumatic system to operate. The actuator receives signals from a thermostat or a control system. It then adjusts the damper position accordingly. This process may seem simple, but it requires precision. Inaccuracies in operation can lead to discomfort or energy waste.

The importance of the Damper Actuator cannot be overstated. It not only regulates airflow but also impacts air quality. An inefficient actuator may fail to provide the right airflow, leading to unbalanced conditions. It's vital to regularly assess and maintain these units. Their role in modern buildings is often overlooked, yet it deserves our attention.

What is a Damper Actuator?

A damper actuator is a crucial component in HVAC systems. It regulates airflow through ducts by adjusting the position of dampers. These devices can be controlled manually or automatically. Automated systems enhance efficiency and response times. According to a 2022 industry report, about 30% of energy consumed in buildings is related to heating, ventilation, and air conditioning. Properly functioning dampers can significantly reduce this energy use.

Damper actuators come in two main types: pneumatic and electric. Pneumatic actuators use air pressure to move dampers. Electric actuators utilize motors and can be programmed for precise control. The choice between them depends on specific system requirements. Often, there are concerns regarding reliability. Sometimes, actuators fail to respond due to inconsistent power supply or mechanical blockage. Industry data shows that regular maintenance can prevent up to 60% of such issues.

Implementing smart technology can optimize damper actuator performance. Smart systems can monitor real-time airflow and adjust accordingly. However, this technology can be costly. Not all buildings can afford advanced systems. Many older buildings still rely on traditional methods. This gap indicates a need for a balanced approach in upgrading HVAC technology while considering budget constraints.

What is a Damper Actuator and How Does It Work?

| Dimension | Description |

|---|---|

| Definition | A damper actuator is a device that controls the position of a damper in HVAC systems to regulate airflow and temperature. |

| Types | Electric, Pneumatic, and Hydraulic actuators are the primary types used based on the application requirements. |

| Working Principle | The actuator receives signals from a controller to open or close the damper, adjusting airflow in response to changes in temperature and pressure. |

| Applications | Used in HVAC systems, industrial processes, and critical environments like clean rooms to maintain desired conditions. |

| Benefits | Improves energy efficiency, provides better temperature control, and enhances indoor air quality. |

| Maintenance | Regular inspection and cleaning are necessary to ensure proper operation and longevity of the actuator. |

Types of Damper Actuators and Their Applications

Damper actuators play a crucial role in HVAC systems. They control airflow in ducts and optimize indoor climate. Understanding their types can help improve energy efficiency and comfort.

There are three main types of damper actuators: electric, pneumatic, and hydraulic. Electric actuators are widely used due to their versatility. They can operate quickly, responding to control signals within seconds.

Pneumatic actuators, on the other hand, use compressed air for operation. These are often favored in large industrial applications. According to a recent market report, electric actuators account for approximately 58% of all damper actuator sales.

Hydraulic actuators are less common but essential in specific scenarios. They provide significant force for heavy dampers. The choice of actuator depends on factors like application type, required speed, and installation space. Each type has its pros and cons, and engineers must consider these carefully.

Some actuators may struggle with extreme temperatures, while others might require regular maintenance. Thus, understanding these details can be challenging yet vital for optimal system performance.

How Damper Actuators Function Mechanically and Electrically

Damper actuators play a crucial role in managing airflow within a building. They can be mechanical or electrical, each with distinct functions.

Both types have their own set of challenges. Mechanical systems may lack precise control, leading to less efficient airflow regulation. Meanwhile, electrical actuators can suffer from power outages, making them unreliable in critical situations. Understanding these mechanics helps in recognizing areas for improvement. Regular maintenance is essential for both types to function at their best.

Factors Influencing the Performance of Damper Actuators

Damper actuators play a crucial role in controlling airflow. Several factors can influence their performance, making it essential to consider them for optimal function.

One key factor is the actuator's size. A properly sized actuator will provide better response times. An oversized actuator may lead to inefficiencies. Its movement might be too slow, resulting in delayed adjustments. On the other hand, an undersized actuator could struggle to open or close dampers fully.

Another important aspect is the power source. Actuators can be electric, pneumatic, or hydraulic. Each type has specific advantages and drawbacks. For instance, electric actuators are often more precise but may require more maintenance. Always ensure the power source matches the actuator’s requirements for efficient operation.

Tips: When selecting a damper actuator, assess the environmental conditions. Dust, humidity, and temperature can affect performance. Regular maintenance is necessary for optimal function. Monitor the actuator's operation for any signs of wear or malfunction to prevent downtime.

Common Issues and Maintenance Tips for Damper Actuators

Damper actuators play a crucial role in HVAC systems. They regulate airflow and maintain temperature control. However, like any mechanical device, they may encounter common issues. Understanding these problems can help in the maintenance process.

One frequent issue is a stuck actuator. Dust and debris can accumulate, preventing it from moving. Regular cleaning can mitigate this. Check for physical obstructions regularly. Sometimes, the actuator may not respond to control signals. This could indicate a fault in the electrical components or connections. Inspecting wiring for damage or corrosion is essential.

Maintenance should also include lubricating moving parts. Keeping the components well-lubricated can enhance performance and extend lifespan. Regular checks can uncover wear and tear. Ignoring small issues might lead to bigger, costlier repairs later. Keeping a maintenance schedule can help identify potential problems early.