JHY PCB Blog Hub

Your Source for Expert PCB Design, Manufacturing, and Assembly Insights – Stay Informed with 2025 Trends!

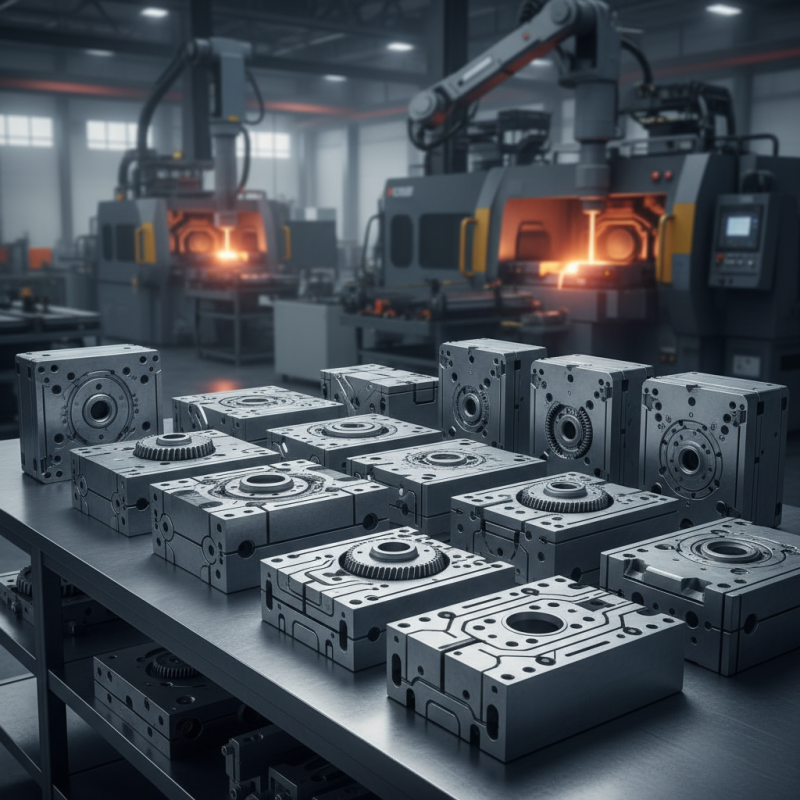

Top 10 Tips for Choosing Die Casting Molds?

Choosing the right Die Casting Molds is crucial for success in manufacturing. According to a report by ResearchAndMarkets, the global die casting market was valued at over $10 billion in 2022. This industry continues to grow, driven by increased demand for lightweight materials in automotive and aerospace sectors.

Selecting appropriate die casting molds involves several factors. The quality of the mold can significantly affect the final product's performance and cost. Reports indicate that around 30% of manufacturing defects are due to poor design and mold selection. This highlights the importance of careful consideration in your choices.

Many manufacturers overlook the significance of mold maintenance. Regular inspections can prevent costly downtime. However, some companies still underinvest in this area. Ensuring proper mold upkeep can extend its lifespan considerably. As the die casting industry evolves, staying informed about innovations can help businesses make better mold choices.

Understanding Die Casting and Its Importance in Manufacturing

Die casting plays a crucial role in the manufacturing sector. This process involves forcing molten metal into molds, creating parts with excellent dimensional accuracy. According to a recent industry report, the die casting market is expected to grow by 6% annually, highlighting its significance in producing complex shapes efficiently.

When selecting die casting molds, understanding your specific needs is vital. One tip is to consider the alloy type you will be using. Different metals, such as aluminum and zinc, have distinct properties that affect mold design. Additionally, evaluate the projected production volume. High volumes require robust molds that can withstand wear and tear, while lower volumes may allow for cost-effective options.

Design optimization is also essential. Simplified shapes help reduce costs, but intricacies may be needed for specific applications. Pay attention to the mold’s cooling system. Efficient cooling can significantly enhance the quality of the final product.

Reflecting on the importance of these factors can lead to better decision-making. A poor choice often results in higher costs and delays. Therefore, understanding die casting is not just about the process but also about making informed, strategic choices.

Key Factors to Consider When Selecting Die Casting Molds

When selecting die casting molds, material selection is critical. Consider how the mold material affects durability and heat resistance. Steel is strong and long-lasting, while aluminum is lighter but may wear out sooner. Think about the trade-offs between cost and longevity. Sometimes, the cheaper option can lead to higher long-term expenses.

Design aspects also play a vital role. The complexity of the part being cast can dictate mold design. Intricate shapes may require more advanced molds, increasing costs. Always review prototype options before finalizing the design. Mistakes at this stage can be costly. Also, ensure efficient cooling channels. Poor cooling can lead to defects in the final product.

Lastly, consider production volume. The expected batch size can influence mold selection. High-volume production justifies a significant investment in durable molds. However, for smaller lots, opting for less expensive molds may be practical. Balancing these factors can be complex, but it's crucial for successful die casting. It often requires careful consideration and reassessment to achieve the best outcomes.

Materials Selection for Durable and Efficient Die Casting Molds

Choosing the right materials for die casting molds is crucial. The durability and efficiency of a mold depend largely on its construction materials. Aluminum alloys are often favored. They provide good thermal conductivity and resistance to metal wear. However, they may not handle high-temperature operations well.

Steel is another common choice. It offers exceptional strength and longevity. Yet, steel molds can be expensive and heavy. This added weight might complicate the manufacturing process. Additionally, they require longer lead times for production. Careful consideration is needed when weighing these material options.

Sometimes, a mix of materials proves beneficial. Combining aluminum with inserts of steel can improve performance. However, this approach can introduce challenges. The bonding of different materials requires precision to avoid issues. Throughout this process, reflecting on the current choices leads to better decisions in the future. Balancing cost, durability, and efficiency is essential for achieving optimal results.

Evaluating Mold Complexity and Design Considerations

When choosing die casting molds, evaluating mold complexity is crucial. Complex molds might offer superior designs but come with higher costs. According to the Metal Casting Market Report, intricate mold designs can increase production costs by up to 20%. This complexity often requires advanced manufacturing techniques.

Additionally, consider the design considerations involved. For instance, wall thickness plays a significant role in mold design. Consistency in wall thickness should ideally be around 2-4 mm for optimal strength. Variations can lead to weaknesses in the final product. Some analysts note that over 30% of casting failures are due to poor wall design.

Also, think about the cooling channels within the mold. Effective cooling reduces cycle times and improves the overall quality of the casting. Insufficient cooling can lead to defects, which might require costly rework. A study indicates that molds with well-designed cooling channels can improve production efficiency by as much as 25%. The right balance of complexity and functional design is essential for success in die casting.

Cost Analysis and Budgeting for Die Casting Mold Production

When considering die casting molds, cost analysis is crucial. The price of mold materials affects overall expenses significantly. Selecting durable metals can increase initial costs but may save money in the long term. A high-quality mold lasts longer and requires fewer repairs. This approach might seem expensive upfront, but it offers a better return on investment.

Budgeting also plays a vital role. It’s important to outline all potential costs. These include design, production, and maintenance expenses. Sometimes, hidden costs like transportation or storage can arise unexpectedly. This may lead to financial strain. Companies should regularly review their budgets to ensure they remain on track. Updates may be needed as production volumes change or new technologies emerge.

Lastly, communication with suppliers is key. Discussing pricing structures upfront can prevent surprises later. While it’s tempting to choose the cheapest option, this may compromise quality. A balance between cost and value is essential. Taking time to reflect on these aspects often leads to better decision-making.

Top 10 Tips for Choosing Die Casting Molds - Cost Analysis and Budgeting for Die Casting Mold Production

| Tip Number | Tip Description | Estimated Cost (USD) | Budgeting Notes |

|---|---|---|---|

| 1 | Identify the purpose and specifications of the mold. | $500 - $1,000 | Ensure clear requirements to avoid scope changes. |

| 2 | Select appropriate materials for the mold. | $2,000 - $5,000 | Consider durability vs cost for long-term use. |

| 3 | Evaluate the complexity of the mold design. | $1,000 - $3,000 | Complex designs may increase manufacturing costs. |

| 4 | Consider the production volume required. | $1,500 - $4,000 | Higher volumes may justify more expensive molds. |

| 5 | Choose a reliable mold manufacturer. | $200 - $1,000 | Research and verify qualifications before hiring. |

| 6 | Plan for maintenance and repair costs. | $500 - $2,000 | Setting aside a budget can save costs later. |

| 7 | Assess cycle times and efficiency of mold operation. | Variable | Efficiency affects total production costs. |

| 8 | Incorporate design features to facilitate casting. | $300 - $1,500 | Good design reduces rejects and post-processing time. |

| 9 | Request for prototypes or sample molds. | $1,000 - $2,500 | Testing before production can reveal potential issues. |

| 10 | Review total cost of ownership, including setup and operational expenses. | Variable | Consider all factors over the mold's lifecycle. |